As energy efficiency in lighting becomes the standard, the next frontier lies in material efficiency and reducing embodied carbon; critical considerations for facilities managers striving to meet net zero targets. Nigel Harvey, CEO, Recolight

As energy efficiency in lighting becomes the standard, the next frontier lies in material efficiency and reducing embodied carbon; critical considerations for facilities managers striving to meet net zero targets. Nigel Harvey, CEO, Recolight

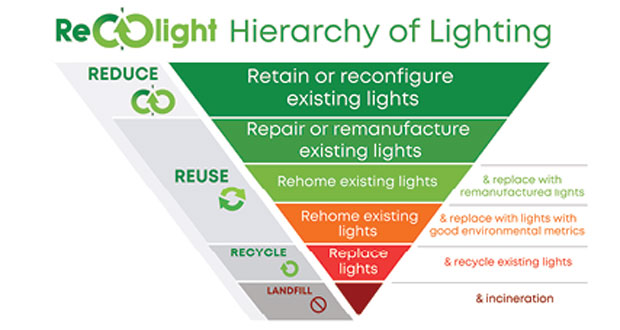

The waste hierarchy is a well-established system to prioritise the most sustainable actions. At its simplest is the mantra “Reduce – Reuse – Recycle”. In an amended format, focused on lighting, Recolight’s “Hierarchy of Lighting” provides facilities managers with a framework that orders strategies according to their impact beyond energy efficiency, and into material efficiency.

REDUCE

This means not buying new lighting if the old lighting does the job – or only replacing lighting which is not energy efficient and cannot be upgraded. Use daylight wherever possible, both to reduce the number of lights that are installed and to reduce the amount of time they are in use.

REUSE OR UPGRADE LIGHT FITTINGS

A growing trend in the lighting sector is the upgrade and reuse of existing fittings, particularly through retrofitting LED technology. This approach not only improves material efficiency but also preserves embodied carbon; the emissions associated with manufacturing and distributing new products. There may be real commercial opportunities for FMs to be involved in the provision of such services, working with a manufacturer to ensure ongoing compliance with relevant product standards.

Upgrading to LED does not have to involve wholesale replacement. Instead, existing fluorescent fittings can be retrofitted, reducing disruption, avoiding additional ceiling work, and often delivering cost savings. Most importantly, the embodied carbon emissions are significantly lower compared to installing new luminaires which is a key consideration for organisations with carbon reduction commitments.

Upgrading to LED does not have to involve wholesale replacement. Instead, existing fluorescent fittings can be retrofitted, reducing disruption, avoiding additional ceiling work, and often delivering cost savings. Most importantly, the embodied carbon emissions are significantly lower compared to installing new luminaires which is a key consideration for organisations with carbon reduction commitments.

Upgrading a luminaire and returning it to its original location is typically more straightforward and less resource-intensive than relocating it or supplying it to a third party. Industry estimates suggest that retrofitting existing fittings with LED sources can halve the embodied carbon compared to new products.

Recolight operates with a range of partners that can help organisations looking to reuse lighting products. The Recolight Reuse Hub is a dedicated platform designed to connect organisations looking to donate or acquire used lighting equipment.

We also work alongside the Finishes and Interiors Sector (FIS) to identify luminaires and ceiling tiles that are scheduled for removal during building renovations, but which could be reused.

DONATE A LIGHT INITIATIVE: The ‘Donate-A-Light’ initiative enables manufacturers, distributors, and organisations to pass on new, unused, surplus or depreciated lighting stock so it can be put to meaningful use. By donating high-quality lighting products that are no longer required commercially but remain in perfect, unused condition, the industry supports projects that benefit from free lighting equipment. Typical recipients are charities, faith and community groups, and similar.

STANDARDS AND CONFIDENCE IN REMANUFACTURE: To support consistent and reliable upgrades, a new code of practice, BS8887:221 (2024), has been developed. This specification provides a systematic approach to the remanufacture of lighting products, giving clients the confidence that remanufactured luminaires are compliant and fit for purpose.

RECYCLING: THE LAST RESORT

While recycling is often seen as a responsible choice, a circular economy approach requires that it should be the final option after all possibilities for reuse and upgrade have been exhausted. Recycling destroys much of the embodied carbon invested in the original product, recovering only raw materials and losing the energy expended in manufacturing and distribution. For facilities managers, this underscores the importance of prioritising reuse and upgrade strategies over recycling when planning lighting projects.

DRIVING SUSTAINABILITY THROUGH PROCUREMENT

Where upgrade or reuse is not possible, and new lighting is essential, facilities managers can play a pivotal role in embedding sustainability into procurement decisions. This involves scrutinising suppliers’ sustainability credentials, including their commitments to decarbonisation and net zero.

Key questions to ask include:

- Are Environmental Product Declarations (EPDs) available for the products?

- Is the environmental performance of the products independently verified?

- Does the supplier provide TM65 (embodied carbon) or TM66 (circularity) data on the products?

- Does the supplier report on short-term decarbonisation actions as well as long-term net zero targets?

- Do their net zero targets cover all relevant emissions scopes (1, 2, and 3)?

By making sustainability a core purchasing criterion, facilities managers can drive meaningful change across their estates.

PRACTICAL STEPS FOR FACILITIES MANAGERS

Audit Existing Lighting: Assess whether current systems can be upgraded rather than replaced.

Engage with Manufacturers: Seek out suppliers offering upgrade and remanufacture services.

Prioritise On-Site Upgrades: Where possible, upgrade fittings in situ to minimise disruption and resource use.

Evaluate Embodied Carbon: Factor embodied carbon into decision-making, not just operational efficiency.

Scrutinise Sustainability Claims: Ensure suppliers’ net zero commitments and product sustainability data are credible and independently assessed.

CONCLUSION

For facilities managers, moving sustainability in lighting beyond energy efficiency means embracing a holistic approach, prioritising reduction, reuse, and upgrade over replacement and recycling. By leveraging industry standards, engaging with forward-thinking suppliers, and embedding sustainability into procurement, facilities managers can make a significant contribution to their organisation’s sustainability, circularity and net zero journey.