Jason Webb, Managing Director, Electronic Temperature Instruments on the importance of precision temperature control in maintaining vital assets

Jason Webb, Managing Director, Electronic Temperature Instruments on the importance of precision temperature control in maintaining vital assets

Precision temperature control is a critical element in laboratories and research facilities, where breakthroughs in scientific research, pharmaceuticals, and healthcare rely on maintaining specific temperature conditions. The challenge of maintaining steady temperatures in these environments doesn’t come without obstacles to overcome. There are however, some innovative solutions that address these challenges, including the essential role that wireless data loggers play in ensuring accuracy and efficiency.

THE CHALLENGE OF TEMPERATURE CONTROL

Laboratories and research facilities are hotbeds of innovation, where accuracy and consistency are crucial. The challenge lies in maintaining precise temperature conditions, often within narrow tolerances. Fluctuations can jeopardise experiments, compromise the integrity of research, or render pharmaceuticals ineffective.

To overcome these challenges, facility managers and researchers are turning to advanced temperature measurement and monitoring equipment. These technologies not only ensure that temperature conditions are met but also enhance efficiency, save time, and reduce costs.

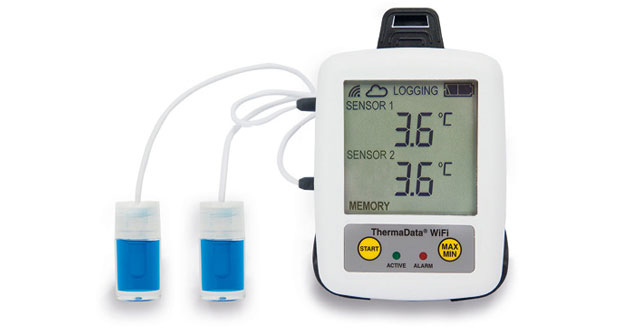

Modern laboratories and research facilities are also equipped with state-of-the-art temperature measurement and monitoring tools. These tools include sensors, thermostats, and what we believe to be the star of the show, wireless data loggers.

WIRELESS DATA LOGGERS: THE UNSUNG HEROES

Wireless data loggers have revolutionised the way temperature is monitored and controlled. These unassuming devices are quietly making a significant impact on laboratory operations. This is largely down to them continuously measuring temperature and wirelessly transmitting data to a WiFi router. This real-time monitoring ensures that any deviations from the desired temperature range are promptly detected and addressed.

The data transmitted by these loggers can be accessed from anywhere in the world, making remote monitoring a reality. Researchers and facility managers can keep an eye on temperature conditions, even when they are miles away from the facility. The loggers maintain a detailed temperature history record, presented in clear and simple graphs. This historical data is invaluable for analysing temperature trends, ensuring conditions have been consistently maintained, and identifying any anomalies.

THEIR ROLE IN VACCINE STORAGE AND MANAGEMENT

The importance of precise temperature control is particularly evident in vaccine storage and management. Many vaccines are sensitive to temperature variations and must be stored within a specific temperature range to remain effective.

These devices provide continuous monitoring of vaccine storage units, offering peace of mind to healthcare professionals, pharmaceutical companies, and government agencies. The temperature history records generated by data loggers serve as a vital tool in demonstrating the proper storage conditions of vaccines, especially in times of vaccine distribution on a global scale.

Pre-pandemic, temperature monitoring of vaccines was carried out manually every few hours. Someone would have to enter the insulated container, opening the doors which let in potentially damaging amounts of heat. If something went wrong between measurements, a few hours was more than enough time for some vaccines to be lost before the next measurement was taken. However, measuring any more regularly would slow transit, ultimately increasing the demand for the resources such as dry ice that are required to keep the vaccines cool. Vaccines also have a limited lifespan so more time in transit limits their shelf-life once they arrived at the medical centre. The World Health Organisation estimates that over 50 per cent of vaccines worldwide are wasted each year. A great number of these are lost due to inefficient delivery and storage.

Wireless data loggers have revolutionised the market. They monitor and record the temperatures in both storage and transport facilities and relay it in real-time. Access to real-time data is vital. WiFi-enabled data loggers transmit data via the cloud to be stored on local devices. They allow for immediate action to be taken if any issue arises with cooling equipment.

MONITORING DURING QUIETER PERIODS

One of the often-overlooked benefits of wireless data loggers is their ability to ensure the integrity of temperature-controlled items when commercial premises are closed, which is especially pertinent during the festive season. Whether it’s a laboratory, a pharmaceutical storage facility, or a research establishment, these facilities often have periods of closure, especially at Christmas.

Wireless data loggers continue to monitor and record temperature conditions even when the premises are empty and the doors are locked. This is crucial for maintaining the quality of temperature-sensitive items, such as research samples, pharmaceuticals, or perishable goods. In the event of a temperature deviation, these devices can send alerts to designated personnel, allowing for timely intervention, even when nobody is on-site.

Precision temperature control is an indispensable aspect of laboratories and research facilities. Whether it’s the pursuit of ground-breaking scientific discoveries, the development of life-saving pharmaceuticals, or the distribution of vaccines to safeguard public health, wireless data loggers play a vital role in preserving the integrity of temperature-sensitive assets. Their real-time monitoring capabilities, global accessibility, and comprehensive temperature history records contribute to a transformative impact on the world of science and research. During periods of closure, these devices provide an extra layer of assurance that the controlled environment remains just that – controlled – safeguarding valuable research and critical inventory.