FREE HEATING

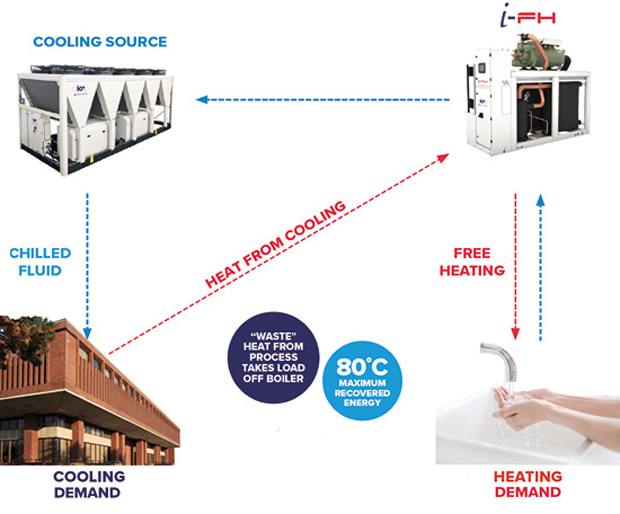

Something less obvious than Free Cooling, but equally effective, can be applied to the heating load. For analogy, we can call it ‘Free Heating’ and a heat pump is the technology that enables it. Heat pumps rely on one of the most energy-efficient methods of heating: the transfer of free thermal energy from outside to inside based on the difference in temperature between the two. What not everybody in the industry does though is look at cooling and heating at once. There are new opportunities ahead if we start looking at heating from the cooling perspective and the opposite.

While pure heating heat pump solutions require external (sustainable) heat sources such as air or (ground) water, combined heating and cooling applications provide the unique opportunity to reclaim or harvest energy, available within the same plant or building. Chillers and cooling plant used to cool manufacturing processes and facilities generate waste heat that typically gets lost to the atmosphere. This heat does not have to be wasted and can be harnessed effectively by Industrial Free Heating (i-FH) units.

Over the last few years, innovations in process cooling and heating systems have led to innovative designs that can offer significant benefits compared to the systems that they are designed to replace. With new generation, low global warming potential HFO refrigerants, it’s possible to achieve temperatures of even 120 degrees Celsius with water-sourced heat pump systems.

RETROFIT TO VSD

Controlling the flow of air and water in process temperature control systems is an effective, permanent way to meet the ever-changing demands put on a system and enhance its efficiency. By installing a Variable Speed Drive or VSD (an electrical/electronic system that provides infinitely variable speed control of AC induction motors) you can meet varying system flow rate requirements or just increase energy efficiency. Payback on an installed system can be as little as six months.

Variable speed components meet the actual load required during any given time over a wide operational range, meaning their speed and output varies to reflect the conditions and demands. By precisely matching output to the cooling demands, compressors and fans operate at their fastest levels when demand is high, and modulate to slower levels when demand is less. The result is lower annual energy use and typically smaller annual energy bills. This is especially true when compared to constant volume units, where the load is either on or off.

SUBSCRIBE TO MORE EFFICIENT TECHNOLOGIES

Innovation and new technologies usually bring increased efficiencies, but organisations are focused on doing more with less, which also means counting every penny in their capital budgets to ensure the expenditure will provide the best return on investment.

When capex is an issue, the traditional alternative to capital investment in purchasing and installing new equipment, has been hire. But now there are more flexible options, with rental schemes. A membership or subscription type of a long-term rental agreement offers access to the latest process temperature control technology, maintenance, and equipment upgrades – all with the flexibility of an operating expense. This new subscription model allows organisations to transform their process temperature control system from a fixed asset into a dynamic solution that will be up-to-date with their changing business and process needs.

A complete HVAC and process temperature control packaged solution should comprise the new equipment, preventive and 24/7 emergency maintenance, replacements and upgrades. All the elements of an all-inclusive, monthly rate contract are tailored to the process’ needs and based on a detailed assessment by the service provider’s engineers.

PLANNED PREVENTIVE MAINTENANCE

The traditional approach to maintenance relies on a calendar or hour metre to determine when equipment is serviced. But technology offers actionable information that means carrying out maintenance when it is needed and not just because the schedule says it is time.

Preventative, predictive or reliability-centred maintenance uses testing, diagnostics and computer modelling to identify actual maintenance needs. This approach hinges on establishing a performance baseline for the temperature control systems based on the performance of similar systems. Systems are continuously monitored, and their actual performance is compared to benchmark data. As a result, it is possible to identify potential problems and schedule maintenance before they can cause systems to fail.

With budgets under pressure, predictive maintenance is a good mean of controlling costs and reducing the likelihood of a temperature control system failure that could shut down your operations.

REMOTE MONITORING SERVICES

Alongside a preventive and predictive maintenance approach, there are technologies and services available that allow you to have 24/7 access to live condition updates and the history of your assets, allowing you not only to oversee performance, energy consumption, but also remotely change set–points for better uptime, productivity, and efficiency. With these capabilities, you can combine data analytics, connectivity and expert support to maximise productivity and the operational and energy efficiency of the heating and cooling systems.

We calculate that Remote Monitoring Service customers can reduce maintenance visits at their site by 50 per cent, resolve 75 per cent of the issues on a first visit and by up to 55 per cent can reduce the operational expenses related with temperature control equipment.

Remote monitoring technology can monitor the reliability of temperature equipment like chillers, boilers, pumps, air handling units and fan coils. It is also compatible with new and legacy equipment, rented or owned and works with customer’s building management systems. By putting the data to work, you can not only have full visibility of the units and expert support to optimise and maximise the equipment’s productivity, but can leverage this intelligence to better plan investments and resources to improve your business’ profitability and growth.