WATER TREATMENT

Water treatment is the most forgotten service element in the chilled water industry but is also one of the most important ones for a system’s reliability and its efficient operation. Most maintenance engineers know that if a chiller’s water and glycol mix is incorrect, the effects can be rapid and disastrous, leading to corrosion, system deterioration, and leaks, as well as the build-up of rust, scale, algae and debris. Chilled water needs to meet several criteria to be used and the PH needs to allow the chemical makeup to remain stable and not create a chemical reaction.

EC FANS

From an energy usage perspective, chillers effectively comprise two halves – high pressure and low pressure, and the closer those two sides are, the more efficient the chiller. One of the key components within a chiller that will impact performance and energy consumption are the EC (Electronically Commutated) fans.

EC fans operate using a DC motor rather than an AC motor, which in turn not only offers a much more efficient fan performance, but also lower noise levels. Engineers are often put-off by the investment in EC fans, however, with a payback period of just six-12 months, can start to make permanent energy savings from just the second year. If we add variable fan speed control, a further 12-14 per cent energy savings can be made compared to standard on/off fan speed control.

ADIABATIC COOLING

The addition of adiabatic cooling offers a cost-effective alternative to a cooling tower by improving the carbon footprint and providing significant savings on water usage. These evaporative coolers are designed to operate at optimal efficiency in high ambient temperatures. The units use fans to operate the cooling for most of the year with a spray system that only activates during periods of high ambient temperatures. The spray activity is tightly monitored using a pulsing mechanism to ensure minimum adiabatic cooling is provided for any given load and ambient condition. This control reduces water consumption and running costs for a long, fault free lifespan.

Adiabatic enhancements can be fitted to both new and existing air-cooled equipment. Without requiring energy to provide the cooling effect, the adiabatic enhancement can reduce the temperature of the ambient air by as much as 20°C. A reduction of 10°C alone can generate a 13 per cent reduction in energy consumption – delivering immediate cost savings and environmental benefits.

CONCLUSION

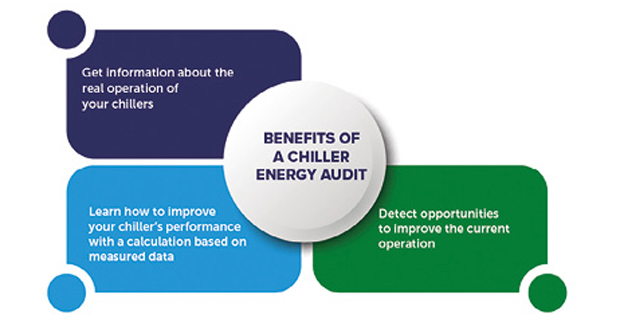

From upgrading the internal elements of a chiller to factoring free cooling or free heating technologies, this variety of tips and techniques will allow you to start taking back control of your site’s energy consumption and improving profitability. Start by calling your temperature control partner and undertake an energy analysis audit to get a true picture of all areas that need to be addressed to improve your energy efficiency and reduce your overall costs.